Contents

Product design and prototyping have come a long way from hand-drawn sketches and manual measurements.

Traditional methods, like taking manual measurements or building CAD models from scratch, can be tedious and error-prone. Today, the emergence of 3D offers facilitates designers and engineers to bring ideas to life. The application of 3D scanning tools has been the engine for working efficiency and model quality.

But how exactly does 3D scanning enhance the design process? And what makes it a game-changer for modern product development? Let’s explore its benefits, applications, and real-world impact.

3D Scanning Work in Product Design

3D scanning captures the physical geometry of an object and converts it into a precise digital model. But how exactly does this process integrate into product design and prototyping?

How Does 3D Scanning Work?

Data Capture: Using lasers, structured light, or photogrammetry, a 3D scanner collects millions of data points from an object’s surface, creating a point cloud that maps its exact shape and dimensions.

Mesh Generation: Specialized software processes the point cloud, connecting the dots to form a 3D mesh, a digital representation of the object’s surface.

CAD Model Refinement: The mesh can be imported into CAD (Computer-Aided Design) software, where designers clean up, modify, or enhance the model for further development.

Prototyping & Testing: Once refined, the digital model can be used for 3D printing, simulations, or CNC machining, allowing rapid iteration and testing before mass production.

Is It Necessary to Invest in 3D Scanning for Product Development?

Guys, absolutely worth the investment, considering the long-term benefits the tools will bring.

1. Faster Prototyping

Traditional prototyping often involves manual measurements and labor-intensive CAD modeling. Loads of painstaking work, to be honest.

With 3D scanning, engineers can quickly capture an object’s exact dimensions and convert it into a digital model in hours, not days! When serving your 3D printing projects, its accelerating in prototyping is more mind-blowing. That is to say, 3D scanning allows rapid physical iterations and faster time-to-market.

2. Improved Accuracy

Human error in manual measurements can lead to flawed designs and costly revisions. 3D scanning tools eliminate guesswork by capturing details down to sub-millimeter precision. Whether refining complex geometries or ensuring parts fit perfectly, scanned data ensures higher accuracy in digital models and final products.

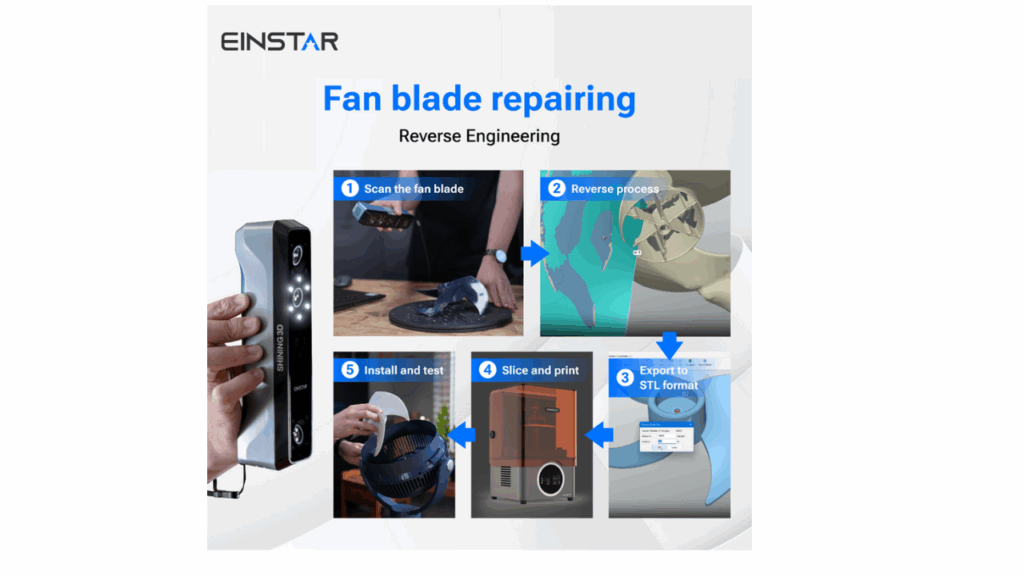

3. Reverse Engineering Made Simple

Many industries rely on reverse engineering to improve or replicate existing products. Instead of starting from the beginning, designers can scan a physical object, whether a competitor’s product, a legacy part, or a hand-sculpted prototype, and convert it into an editable CAD file. This is invaluable for:

- Upgrading outdated components

- Analyzing competitor products

- Recreating discontinued parts without the original blueprints

4. Design Iteration & Customization

Designers often need to tweak and refine models multiple times before finalizing a product. 3D scanning allows for quick adjustments by providing a baseline digital model that can be modified in CAD software. This is especially useful for:

- Custom-fit products (e.g., medical devices, ergonomic tools)

- Aesthetic refinements based on real-world feedback

- Rapid testing of multiple design variations

5. Significant Cost & Time Savings

By reducing manual labor, minimizing errors, and speeding up prototyping, 3D scanning cuts development costs across the board. Fewer physical prototypes are needed, and manufacturing delays due to design flaws are drastically reduced.

Why the EINSTAR VEGA is a Top Choice for Most of Your Projects

The EINSTAR VEGA has been top on the buyer’s list as a powerful, versatile, and user-friendly solution that accelerates development.

The portable 3D scanner facilitates product development with professional-grade 3D scanning in a compact, wireless package.

It comes with dual-mode scanning that adapts to any project, from capturing intricate details in HD Mode (0.05mm accuracy) or rapidly scanning large objects in Fast Mode.

What’s more, EISNTAR VEGA can scan anything from mechanical parts to organic shapes, then export directly to CAD or 3D printing software in standard formats. Real-world tests prove its capability for reverse engineering, rapid prototyping, and quality control — all with significantly lower costs and faster turnaround than traditional methods.

Welcome to the EINSTAR Community

Ready to transform your design process? The EINSTAR VEGA makes professional 3D scanning accessible, without the professional price tag.

Discover more. Create better. Build smarter.Click here to join EINSTAR community: https://forum.einstar.com/