Contents

As an important part of active optical devices, the 40G QSFP+ optical transceiver module plays a very important role in the field of broadband communication networks. With the surge of optical network information capacity, the speed of QSFP+ optical transceiver module increases gradually, and its heat flux increases gradually. The heat dissipation performance of the module has become an important factor restricting its further development. In this paper, the 40G QSFP+ SR4 optical transceiver module is taken as the research object. By analyzing the heat transfer path of the QSFP+ optical module, the thermal model of the optical module is established. The effects of different materials, contact thermal resistance and layout of heating devices on the temperature field of the optical module are obtained by simulation analysis.

Why Heat Dissipation Is Important for Optical Modules

The rapid development of modern electronic technology is closely related to the continuous progress of thermal control technology. Thermal design has become an important part of optoelectronic components, devices, and modules. The heat flux density of early optical transceiver modules, such as SFP + packaging, generally does not exceed 2W / in^2. This kind of optical module generally does not need to be equipped with a heat sink for heat dissipation. With the development of optical modules towards high-speed, high integration, and miniaturization, their heat flux density continues to increase, resulting in an increase in calorific value and a sharp rise in temperature. The shell temperature of the laser in the commercial optical module shall not exceed 70 ℃, which is 15 ℃ lower than that of other components of the exchange disk where the optical module is located. As a result, the temperature requirements of the optical module are extremely harsh. The heat dissipation problem has become one of the key technologies restricting the development of the optical transceiver module technology.

Heat Dissipation Path of 40G QSFP+ Optical Module

After the QSFP+ optical module is inserted into the panel, a small part of the heat generated inside is dissipated by natural convection of the surrounding air, and most of it is dissipated by heat conduction. The heat is transferred from the high temperature end to the low temperature end. The module heat is transferred upward to the packaging shell and radiator, and then dissipated by the radiator through convection and radiation to the main board.

Because the contact surface between the optical module packaging shell and the heat sink is not smooth on the micro level, there must be air and other media, so there is always a certain contact thermal resistance on the contact surface. In order to improve the overall heat dissipation efficiency of the module, it is necessary to reduce the thermal resistance between the optical module and the heat sink as much as possible.

Thermal Model of 40G QSFP+ Optical Module

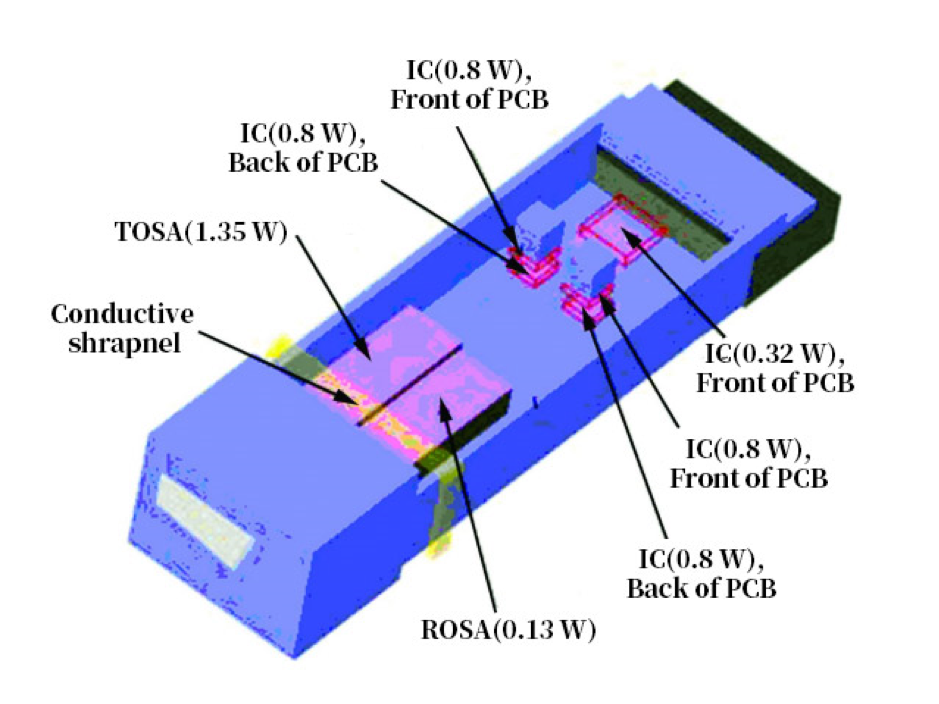

Qsfp + optical module includes TOSA component (transmitterop-ticalsub-assembly), ROSA component (receiver optical sub-assembly) and drive and control IC.

The total power consumption of the 40G QSFP+ SR4 optical module is 5W, and the total power density of the module is 1.34W/cm^2. The heat sink is made of aluminum alloy with a thermal conductivity of 200W / (m·K). The thermal model of QSFP+ optical module is established by using Flotherm software, as shown in the figure below.

In this model, different materials are set for the shell substrate of the QSFP+ optical module, and the effects of different thermal conductivity materials on the temperature field of the optical module are compared and studied. There are four types of shell heat conduction materials, as shown in the table below.

Shell Thermal Conductive Material

| Material | Cast Zinc Alloy | Cast Aluminum Alloy | Copper | Vacuum Chamber Soaking Plate |

| Thermal Conductivity/(W*M^-1*K^-1 | 113 | 169 | 385 | 1000 |

Analysis of Simulation Results

Using Flotherm software, according to different shell materials, contact thermal resistance and device layout, the thermal model of QSFP+ optical module is simulated and analyzed, the module shell temperature data is output and the relevant curve is established. According to the MSA agreement, the heat dissipation performance of QSFP+ optical module focuses on the module shell temperature and the temperature difference between the module shell and the radiator.

Important influencing factors of optical module heat dissipation include:

1) Thermal conductivity of shell. Under the same heat dissipation conditions, improving the thermal conductivity of the shell is conducive to reducing the module shell temperature and the temperature difference between the module shell and the radiator.

2) Device layout. Shortening the distance between the base plate of the heat sink and the heating component is conducive to reducing the module shell temperature and the temperature difference between the module shell and the radiator. Improving the thermal conductivity of the shell is conducive to reducing the influence of device layout on module heat dissipation.

3) Contact thermal resistance. The contact thermal resistance between the module shell and the radiator is an important factor affecting the module heat dissipation. Reducing the contact thermal resistance is conducive to improve the heat dissipation performance of the module, and then reduce the module shell temperature and the temperature difference between the module shell and the radiator.

4) The contact area between the radiator and the module housing. After analysis, by increasing the length of the radiator contact surface, the module shell temperature and the temperature difference between the module shell and the radiator can be reduced by about 1.5 ℃

By comprehensively adopting various measures to improve the thermal conductivity of the shell, reduce the contact thermal resistance and increase the contact area between the module shell and the heat sink, the module shell temperature and the temperature difference between the module shell and the radiator can be improved by about 5 ℃, which can effectively improve the heat dissipation of QSFP+ optical module.

Conclusion

This paper mainly focuses on the heat dissipation related to reliability, and chooses QSFPTEK 40G QSFP+ SR4 optical transceiver module as the research object. Based on the analysis of the heat conduction path in the module, the thermal model of QSFP+ optical module is established, and the effects of different materials, contact thermal resistance and layout of heating devices on the temperature field of the optical module are simulated. The simulation results show that reducing the contact thermal resistance, improving the thermal conductivity of the material and shortening the distance between the heating device and the heat sink can effectively improve the heat dissipation performance of the optical module.