Contents

The crucial first step of IQF processing involves blanching the product, bringing it to the perfect temperature during cooking. A couple of minutes of blanching are all you need to create the perfect result. But how does it work, and what advantages does Octofrost’s blanching machine bring to the table?

Create the ultimate frozen vegetables with this modern technology. Keep reading to find out how the innovative mechanisms within make processing faster, more efficient, improve the appearance and texture of the blanched products and ensure a high yield.

Fine-grained temperature control

During IQF processing, speed plays a key role – but overcooking from the start is certain to doom the product. As a result, Octofrost has designed the ultimate balance between speed and precision, so you can blanch products to your exact desired temperature. The unique Impingement Flash (IF) technology reduces processing time to a minimum, while also reducing time and energy consumption. The IF machine allows you to specify the exact time and temperature you need, to be precisely what you need for any given product.

For added customizability, we offer our clients the unique ability to add a second temperature zone to their Blancher, for processing particularly difficult products which may be prone to over-blanching.

You have complete control over the temperature variations, as the different sections of the blancher can be turned on or off, suiting your production process better. Additionally, you’re able to speed up or slow down the intake, to further customize the processing to your needs. The processors can opt to use either steam or water in the blanching process.

Efficiency

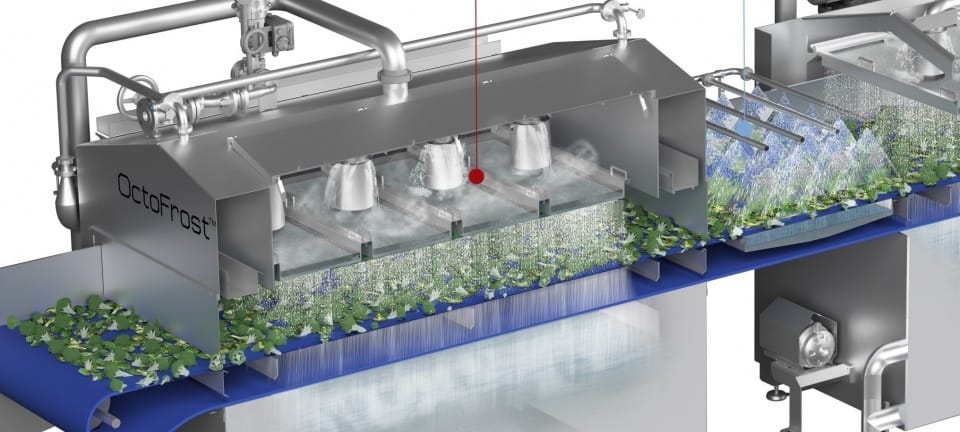

Thanks to the Cross-Flow water system, a high volume of water used during blanching is recirculated, and quickly warmed up to fit your specified temperature. The hot water drops from above onto the product, showering it, and filters through it, to then exit from the blancher. Then, it is rerouted to the water recycling tank, where it is both filtered and heated using steam injection, to then be reused.

This process saves water and preserves resources while maximizing the efficiency of processing your product. The Octofrost Blancher has the correct temperature, every step of the way.

The steam injection method is one of the most efficient methods of heating water, which helps use the energy involved in the process to its greatest extent.

Excellent heat transfer

Unlike other methods of heat transfer, the rain shower system guarantees the fastest possible time. This is invaluable when processing products where speed is a key factor and improves production. The temperature on the surface closely follows the temperature at the core of the product, within a matter of seconds. This ensures heating is uniform, and you don’t have unfortunate cases where some parts of the product are undercooked on the inside.

Additionally, the even spread of heat from the rain shower system helps create a uniform blanching experience for your product. This ensures high yield, as there’s no need for post-processing blanching steps or throwing parts of the processed goods away.

The rain shower system

Designed by talented engineers, with decades of experience, over many years – the rain shower system is one of the key elements that make Octofrost’s production line stand out. With control of up to 0.2 °C – you’re offered a level of control seldom seen in frozen food processing. Create premium-quality goods by tailoring your blanching temperature to the exact one needed by your products, and you will notice a marked quality improvement.

Additionally, the soft, uniform fall of rain over the product with nothing but gravity propelling it helps preserve the product’s structural integrity. This becomes especially important when blanching products that are notorious for breaking down during processing. In addition, the water can permeate a higher layer of product, maximizing capacity utilization.

A final benefit of the rain shower system is the level of hygiene it offers. With extraordinary permeating capabilities, it manages to thoroughly clean the product during blanching– saving time and skipping over a step, making processing faster.

Variety

One of the greatest strengths of our design is that the Blancher can run on many distinct types of food products, and create an overall excellent result. That is partly due to the customizability the blanching equipment was designed with, initially. By preserving the integrity of the raw product, using fine raindrops to blanch the product, and creating precise temperature zones for blanching, it’s easier than ever to work with many different fruits and vegetables.

Additionally, it’s possible to work with grains, pulses, and tropical fruits to create one-of-a-kind premium frozen goods.

High yield

When incorporating the Blancher into your vegetable processing line, you will notice that your yield can now easily increase. That is thanks to the sizable capacity of the Blancher, with 1 000 to 15 000 kg/h of product processed, permanently. As part of the IQF processing line, the unique bedplate technology guarantees that you will only need minimal maintenance to keep your processing running, without needing to stop production in most cases.

Productivity is further considerably increased by using the different temperature zones to their fullest extent and ensuring the products coming out of the blancher aren’t mushy or soft. Rather, they’re cooked to the exact temperature specified, ready to be processed further down the line.

The infeed can be equipped with different options, to further increase input, while preserving the integrity of the goods.

Easy installation and maintenance

Octofrost is happy to announce our Blancher works perfectly well as part of our official IQF processing line, as well as outside of it. It’s easier than ever to integrate it into your existing business processes and customize it to fit your exact needs. When installing the machine, it will take only a short amount of time before you can fully use it.

We provide excellent maintenance opportunities, with a customer support team dedicated to keeping your equipment running at all points, with dispatched teams of technical experts, should it be necessary.

By ensuring your business starts processing on the right first step, using modern technology, you’ll have time at your advantage – which is key in creating the ideal frozen product.