Contents

In the food manufacturing industry, cold storage facilities play a critical role in preserving the quality and extending the shelf life of products. An important part of achieving this is leveraging advanced technologies and reliable equipment to maintain optimal temperature and humidity levels. One such vital piece of equipment is the Frick Screw Compressor, which serves as the core of many refrigeration systems in cold storage facilities worldwide. In this article, we will discuss the essential role that Frick Screw Compressors play in cold storage and how their unique features contribute to efficient and effective temperature control.

Understanding the Functionality of Frick Screw Compressors

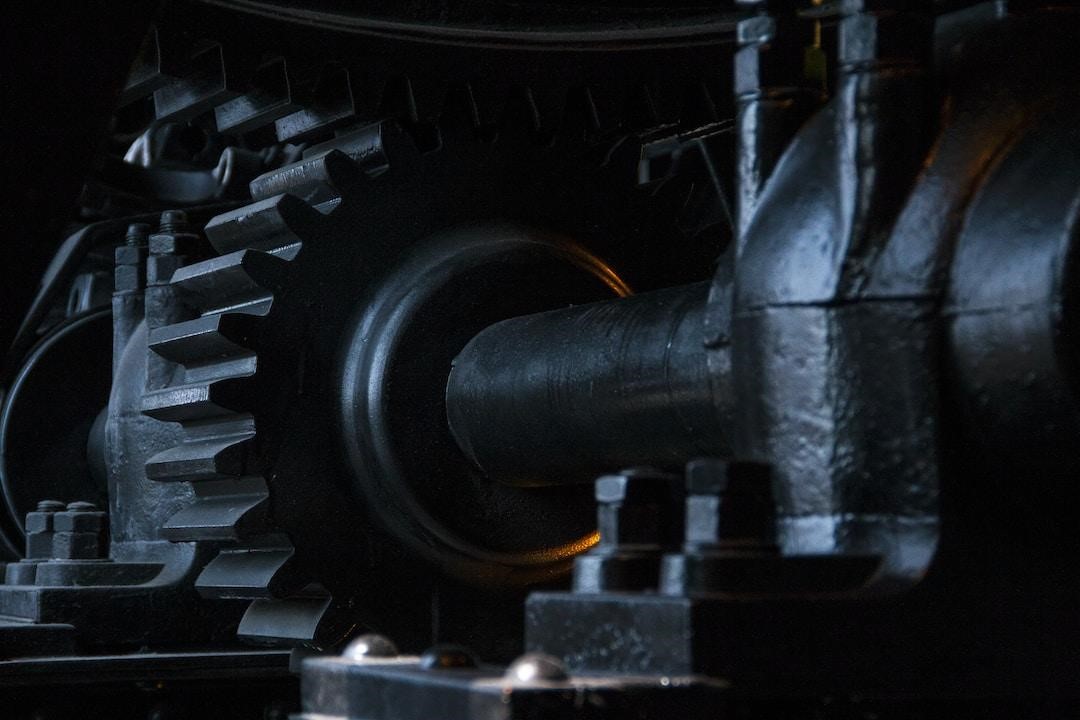

The primary purpose of a Frick Screw Compressor is to convert mechanical energy into compressed refrigerant gas, which is then circulated throughout a refrigeration system to create the desired cooling effect. These compressors utilize two helical rotors or screws that mesh together as they rotate. The process begins when refrigerant gas is drawn into the compressor and carried through the grooves between the screw’s teeth. As the rotors continue to rotate, the gas becomes compressed, ultimately reaching the desired pressure before being expelled from the compressor for further use in the system.

What sets Frick Screw Compressors apart from other compressor types is their efficiency and reliability. They are designed to operate with minimal energy waste and provide consistent performance even under varying loads and operating conditions. This is achieved through advanced rotor profiles, precision-built components, and intelligent control systems that can adjust the compressor’s operation in real time.

Furthermore, Frick Screw Compressors are known for their durability and long service life, thanks to the use of high-quality materials and robust construction. This means that once installed, these compressors can continue to perform reliably for many years with proper maintenance, ensuring a stable temperature and humidity in the cold storage facility.

Energy Efficiency and Cost Savings

A significant advantage of Frick Screw Compressors is their energy efficiency, which translates into cost savings for cold storage facility operators. This efficiency can be attributed to several factors, such as optimized rotor designs, variable speed drives, and advanced control systems that allow the compressor to adapt its performance based on the current requirements of the refrigeration system.

By reducing energy consumption, Frick Screw Compressors help facility operators minimize their operating costs while also contributing to a lower carbon footprint. This is particularly relevant in today’s world, where energy prices are continually fluctuating, and there is increasing pressure to adopt sustainable practices across all industries.

Beyond energy efficiency, they also offer lower maintenance costs compared to other compressor types. Their robust design and quality components minimize the risk of breakdowns and reduce the frequency of required maintenance interventions.

Customization and Flexibility

Another notable advantage of Frick Compressors is their adaptability to a wide range of applications and system requirements. They can be tailored to meet the specific demands of a cold storage facility, ensuring a highly efficient refrigeration system tailored to the facility’s needs.

This customization includes the choice of refrigerant used, compressor capacity, and control algorithms that can be adjusted to suit varying refrigeration loads and storage conditions. Furthermore, Frick offers a variety of compressor models, making it easier to find the perfect fit for each facility’s unique requirements.

By choosing a compressor tailored to their needs, cold storage operators can ensure an optimized refrigeration system that reliably maintains the desired temperature and humidity conditions, preserving the quality of the products being stored.

Supporting a Safe and Sustainable Cold Storage Environment

The role of Frick Screw Compressors in cold storage facilities goes beyond effective temperature and humidity control. These compressors also contribute to a safer and more sustainable environment within the facility for the stored products and the people working there.

With advanced control systems, Frick Screw Compressors can detect and respond to changes in a refrigeration system, reducing the likelihood of failures or abnormal operating conditions that could pose risks to the facility or personnel. Additionally, the use of environmentally friendly refrigerants, coupled with the compressor’s energy efficiency, helps minimize the facility’s environmental impact.

Frick Compressors serve as the backbone of countless cold storage facilities worldwide thanks to their efficiency, reliability, and adaptability. They are a vital component in maintaining ideal storage conditions, ensuring that products remain fresh, safe, and of high quality for consumers and businesses alike.