Contents

How Baghouses Help?

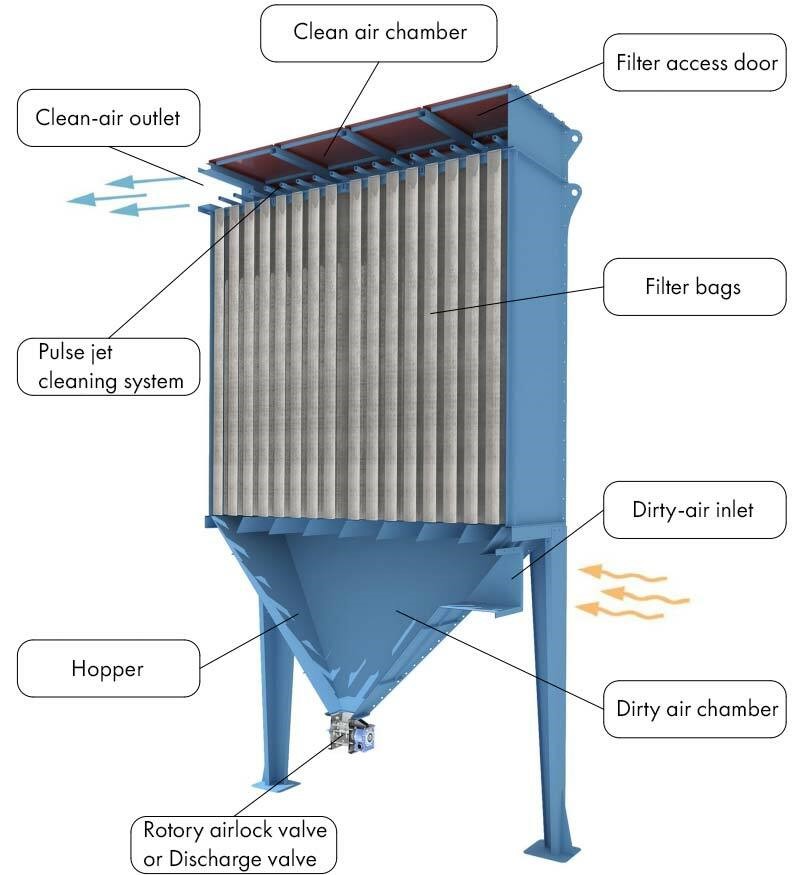

Baghouses, aka baghouse filter, fabric filter, or bag filter are the dust-collectors that uses pleated filters attached within a sheet metal housing or fabric filter bags to eliminate the pollutants formed during industrial practices from the air. Asphalt plant baghouse is the widely utilized dust collection systems since they are not just cost-effective, but also efficient. They work as an air pollution control device, catching dust and hazardous particulates from exhausting clean air and industrial environment. Hence, it is important to choose an ideal one to avoid asphalt plant baghouse problems in future.

Asphalt baghouse dust collectors come in different sizes, design, and capacity as needed by any industrial setting. They also mostly share the same components, like:

- Pickup points and collection hoods to collect dust

- Ductwork for transferring the dust to the collector

- Pleated or felt filters that separate and gather dust straight from the air stream

- Motors or fans to pull dust laden air in the collector

- Dust device or container to collect and dispose the captured dust

Benefits of Baghouse in an Asphalt Plant

In order to choose the right baghouse asphalt plant, one should take note of the following key points.

1) Multi-Stage Dust Removal Structure

- One of its distinctive features is the multi-stage dust reduction technology used in asphalt blending plants.

- This method effectively guarantees raw material usage by recycling the dust based on particle size.

- Reusing leftover powder lowers production costs and also generates extra revenue for the company.

Thus, it is absolutely advantageous to optimize raw material consumption efficiency while maintaining product gradation.

Customers can help ensure the enterprise’s sustainable growth by doing this, which also lowers production costs and improves compliance with environmental requirements. Furthermore, the bag filter system-equipped asphalt batching plant can also satisfy environmental protection standards.

2) Competent Dust Removal

- The asphalt mixing plant for sale’s dust removal system is based on the hi-pressure pulse baghouse filter.

- When compared to conventional methods, the hi-pressure pulse bag filter dust collector provides a more complete and effective removal of dust.

- Its effective ability to remove dust not only satisfies environmental protection regulations set forth by the local government, but it also successfully deters complaints related to environmental problems.

3) Security & Safety

The asphalt batching plant’s flue is fitted with a cold air valve and an over-temperature cease-fire prevention system, which effectively ensures the bag filter can be used safely. Customers can save a significant amount of money by using these devices to efficiently avoid damage to the bag caused by high temperatures, as well as by lowering the frequency of worn part replacement and maintenance expenses.

The asphalt blending plant bag de-dusting system’s main feature is its thorough consideration of the needs of the user in the design, which lowers the cost of usage for the customer while simultaneously improving equipment reliability. Hence, selecting the asphalt batch plant with a filter bag configuration for an asphalt mixing plant increases the success rate! This also clarifies why the bag filters are known as the lungs of the asphalt plant!

Why is it important to Maintain Baghouse of Asphalt Plants?

In asphalt mixers, harsh corrosive gasses and extremely high temperatures are used to test baghouses. Certain factory operations like frequent temperature changes, equipment start-up and shutdown, and fuel switching, pressurize the filter bags. The filter materials are occasionally under a lot of pressure from severe environments, high moisture and dust content, and both.

Maintaining the pressure inside the baghouse chamber is crucial to ensure that bags continue to function properly. Unfortunately, most of the time, consumers wish to use the equipment in the rain as well, which could give tragic results. There have been instances where the bag filters have been severely damaged by bag gasoline and had to be replaced right away.

The process of changing the bags is messy, time-consuming, and necessitates closing down the operation. Before replacing the new bags in the existing cage, all of the bags must be taken out of the top of the baghouse. The task is laborious, especially when cages are involved. If the proper kind of bag filter is installed, users can be confident for the equipment to operate without stress.

In Summary

Environmental awareness is becoming highly prevalent in today’s society, hence, for an enterprise, selecting an asphalt mixing plant with right dust removal system not only fulfils its obligation to protect the environment, but also safeguards the growth of the business.

The asphalt plant bag house is used in the asphalt mixing plant mainly due to its exact recovery, dependable safety, and effective dust extraction. Therefore, for increased production efficiency, cost savings, and environmental compliance, it is important to consider the asphalt mixing plant equipped with a baghouse. Connect with us, we have the best asphalt baghouse for sale to match your needs.